Pedir modelos de aviones personalizados: ¿Es siempre mejor lo caro?

Airplane models are small or large unmanned aircraft models, that serves as a complete replica of an existing or even an imaginary concept of an aircraft.

Model aircrafts can either be flying or non-flying. Flying models range from simple gliders (foam polystyrene) to powered scale models (balsa wood, fiberglass, etc.). More often than not, the non-flying models are made with plastic and injection-molded polystyrene and are displayed or shelved in houses, collection rooms, or museums, because these are not intended to fly.

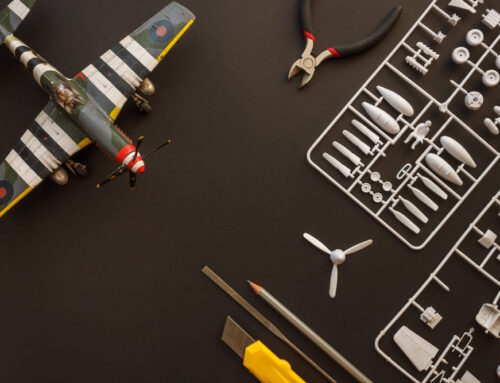

Realistic aircraft models are made from scratch. Usually, model makers would use simple techniques for adding interior and exterior details, removing seams, applying decals, and weathering to make sure the mock-up is realistic, functional, and exceptional.

One may think building a miniature model of an aircraft is pretty simple. But it’s not. The process itself is an art, and the model builder’s experience and skill is critical to the successful creation of a model. Think about this. When aerodynamicists need to run a wind tunnel test (used to test models of proposed aircraft and engine component), they always use the scale model made by a commissioned model maker.

This is why aircraft manufacturers from all over the world would only get skilled craftsmen who have had a lot of experience in this particular field. Aircraft models need to be completed and highly detailed, and must possess the precise instrumentation for the test data. It takes a very long process just to complete ONE aircraft scale model – with some taking hundreds of hours.

Is the “maker culture” expensive?

Due to the advancement of technology, the fabrication industry has experienced a remarkable shift from centralized production to a “made-to-order” scheme which leads them to build to order, rather than to build to stock.

Instead of following the traditional production scheme, model makers would only manufacture a product once a customer places an order. It requires additional waiting time since the items are not in stock, and are not readily made, but it will also allow flexible customization (according to customer’s SPECIFIC preference), rather than just buying a product found on the company’s shelves.

While the “maker culture” is very much present in the model fabrication industry, there are still other companies who simply buy plain models from freelancers or other online suppliers, or hire cheap labor to build models that end up being low-quality. They fail to understand that the success of branding is not about “having customers who know you, but getting customers who buy from you because the product already speaks for itself.”

Having an actual “actual hands-on experience” is critical because it would reflect on the end results.

This brings us to the important question when ordering custom airplane models, Is “Expensive Always Better?”

For consumers, the old adage, “Quality comes with the price,” almost seems like a prayer. They look for the most expensive “product,” because they have the assumption that since it’s more costly, then, it must be that good. Consumers should be wary, too. Some companies sell their products or services too high and just justify the price and your willingness to pay up with this old adage when the quality is relatively equal to other companies.

The feeling of “better,” “advanced,” “high-quality,” and “top-notch,” coming along with an “expensive price tag” is something most people believe. But it’s also just a marketing ploy. The correlation between price and quality has changed over time, and it’s not completely true anymore.

Take this, for instance: for made-to-order or custom-built airplane models, one would be surprised to find that there are a few exceptions.

For instance, the average retail market price of a huge model aircraft is somewhere between $3,500 and $4,000. Yet, a company called ModelWorks Direct builds exactly the same item for only $2,500 – which means a substantial difference, and savings of $1,000 up to $1,500!

If companies pride themselves in making models for those who truly value and appreciate it, then upselling is not an option. Why? It’s simple.

Even for the low fee of the custom masterpiece, they are firm, never to compromise on quality. If the company has a strong brand identity – a positive, and competitive one, getting customers to reach out to you won’t be a problem; nor is pricing lower.

Open to different options

Whether you’re a collector, a hobbyist, or a company representative who’s looking for a supplier to create custom aircraft models, it helps to check and list down ideal companies that could commit to your requirements.

Look for companies with model makers with plenty of years of experience, to make sure you are having your custom aircraft model built by the professionals. Be very keen on the company’s expertise.

Once you find the right model maker for your needs, then take pleasure in seeing your wonderful aircraft model collection grow and grow.